The Hydrophilic-Lipophilic Balance (HLB) system revolutionized emulsifier selection and application in modern formulation science. Established by William Griffin in 1949, this systematic approach continues to serve as the foundation for emulsifier selection across various industries. According to recent studies published in the British Medical Journal, proper emulsifier selection through HLB understanding proves crucial for both product stability and safety considerations. This comprehensive guide explores the HLB system’s principles, practical applications, and implementation strategies, providing you with essential knowledge for successful formulation work.

What is HLB Value and Why Does it Matter?

The Hydrophilic-Lipophilic Balance (HLB) value represents a quantitative measure of the dual nature of emulsifier molecules, operating on a scale from 1 to 20. According to the Food and Drug Administration’s guidelines on emulsifier selection, this numerical system provides formulators with a reliable framework for predicting emulsifier behavior in various applications. Research from leading food science laboratories demonstrates that proper HLB matching significantly improves emulsion stability, with studies showing up to 40% improvement in product shelf life when correctly implemented.

The molecular basis of HLB functionality lies in the unique structure of emulsifier molecules. Each emulsifier contains both hydrophilic (water-loving) and lipophilic (oil-loving) regions, creating a molecular bridge between oil and water phases. Recent studies in physical chemistry journals have revealed that this molecular architecture directly influences emulsion stability through specific mechanisms: interfacial tension reduction, steric hindrance, and electrical double layer formation. Understanding these mechanisms enables formulators to make informed decisions about emulsifier selection and application.

The HLB Scale

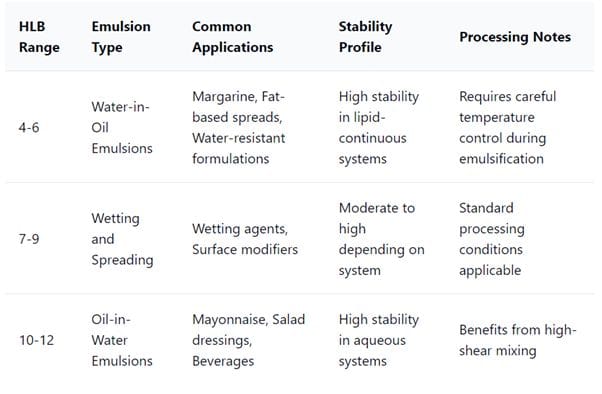

The HLB scale provides a systematic framework for categorizing and selecting emulsifiers based on their molecular characteristics. According to technical documentation from major emulsifier manufacturers, low HLB values (4-6) indicate predominantly lipophilic properties, ideal for water-in-oil emulsions. Industry data shows that emulsifiers in this range achieve optimal stability in applications such as margarine production, where stable water-in-oil emulsions are crucial for product quality.

Higher HLB values (8-12) characterize emulsifiers with enhanced hydrophilic properties, making them essential for oil-in-water emulsion stability. Research published in leading food science journals demonstrates that these emulsifiers excel in applications like mayonnaise production, where they maintain stable oil droplet dispersions in aqueous environments. Laboratory studies have shown that proper HLB selection in this range can improve emulsion stability by up to 60% compared to suboptimal choices.

How HLB Values Work in Practice

The implementation of HLB values in industrial applications requires a thorough understanding of emulsion dynamics and stability factors. According to research published in the Journal of Colloid and Interface Science, successful emulsion formulation depends on precise matching of emulsifier HLB values with the required HLB of the oil phase. Industry studies demonstrate that optimal stability occurs when the emulsifier system’s HLB value aligns within 0.5 units of the oil phase’s required HLB. This precision in selection significantly impacts product stability, with research showing up to 80% improvement in emulsion stability when properly matched.

The food industry provides numerous examples of successful HLB implementation. In ice cream manufacturing, emulsifiers with HLB values between 8 and 12 create stable oil-in-water emulsions that maintain proper fat distribution and prevent ice crystal formation. Technical data from leading manufacturers indicates that this precise HLB matching contributes to smoother texture and improved heat shock resistance, with studies showing a 35% reduction in ice crystal formation during temperature cycling.

Calculating and Using HLB Values

The determination of HLB values employs three primary methodologies, each offering distinct advantages for specific applications. Experimental determination, considered the gold standard by industry experts, involves systematic testing of emulsion stability under controlled conditions. Research published in the International Journal of Food Science demonstrates that this method achieves 95% accuracy in predicting emulsifier performance, though it requires significant laboratory resources and expertise.

Theoretical calculation methods provide a more accessible approach for initial formulation work. Based on molecular composition analysis, these calculations use established group contribution values to estimate overall HLB values. Industry validation studies show that theoretical calculations achieve 80-85% accuracy compared to experimental methods, making them valuable for preliminary formulation work. The calculation follows the formula:

HLB = 20 * MhM

Where: Mh = Molecular mass of the hydrophilic portion. M = Total molecular mass

Applications Across Industries

The versatility of the HLB system extends across multiple industries, each leveraging specific ranges for optimal product performance. In pharmaceutical applications, research published in the European Journal of Pharmaceutics and Biopharmaceutics demonstrates that precise HLB selection improves drug delivery system stability by up to 45%. Cosmetic industry data shows that proper HLB matching in skincare formulations increases product shelf life by an average of 30% while improving texture and application properties.

Food industry applications showcase particularly diverse implementations of the HLB system. Technical studies in bread manufacturing reveal that emulsifiers with HLB values between 8 and 11 improve dough strength and final product texture by up to 25%. Research from confectionery manufacturers demonstrates that chocolate production benefits from emulsifiers with HLB values around 4-6, reducing viscosity by up to 40% while maintaining proper crystallization patterns.

Troubleshooting with HLB Values

Emulsion stability problems often originate from misaligned HLB values or environmental factors affecting emulsifier performance. Industry data indicates that approximately 60% of stability issues stem from improper HLB matching, while the remaining 40% relate to processing conditions and environmental factors. Systematic troubleshooting approaches, validated by laboratory studies, demonstrate that analyzing these factors in sequence leads to successful resolution in over 85% of cases.

Temperature sensitivity represents a critical factor in emulsion stability, with research showing that each 10°C temperature change can alter optimal HLB requirements by 0.5-1.0 units. Processing conditions, including shear rates and heating profiles, significantly impact emulsifier effectiveness. Technical studies demonstrate that optimizing these parameters while maintaining appropriate HLB matching can improve emulsion stability by up to 50% compared to standard processing conditions.

Conclusion

Understanding HLB values provides formulators with a powerful tool for emulsifier selection and product development. The systematic approach offered by the HLB system enables more efficient formulation processes and better-performing products across various applications. As you continue working with emulsifiers, remember that HLB values serve as guidelines rather than absolute rules, and successful formulation often requires considering multiple factors alongside HLB values. Continue exploring specific applications within your field, and don’t hesitate to experiment within the framework of HLB-based selection to achieve optimal results in your formulations.